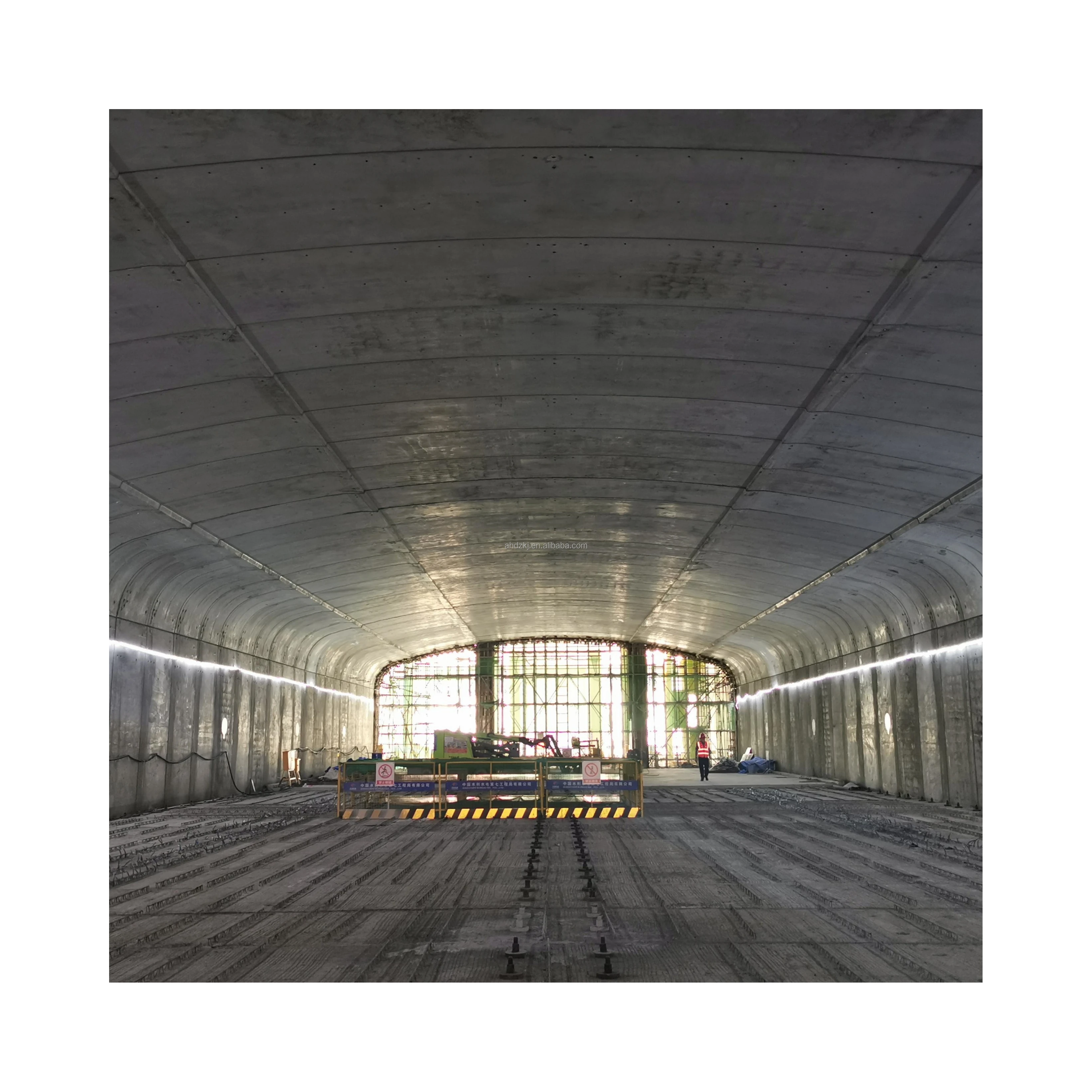

Prefabricated Engineered Durable Strong Steel Frame Train Support Subway Station Building Steel Structure

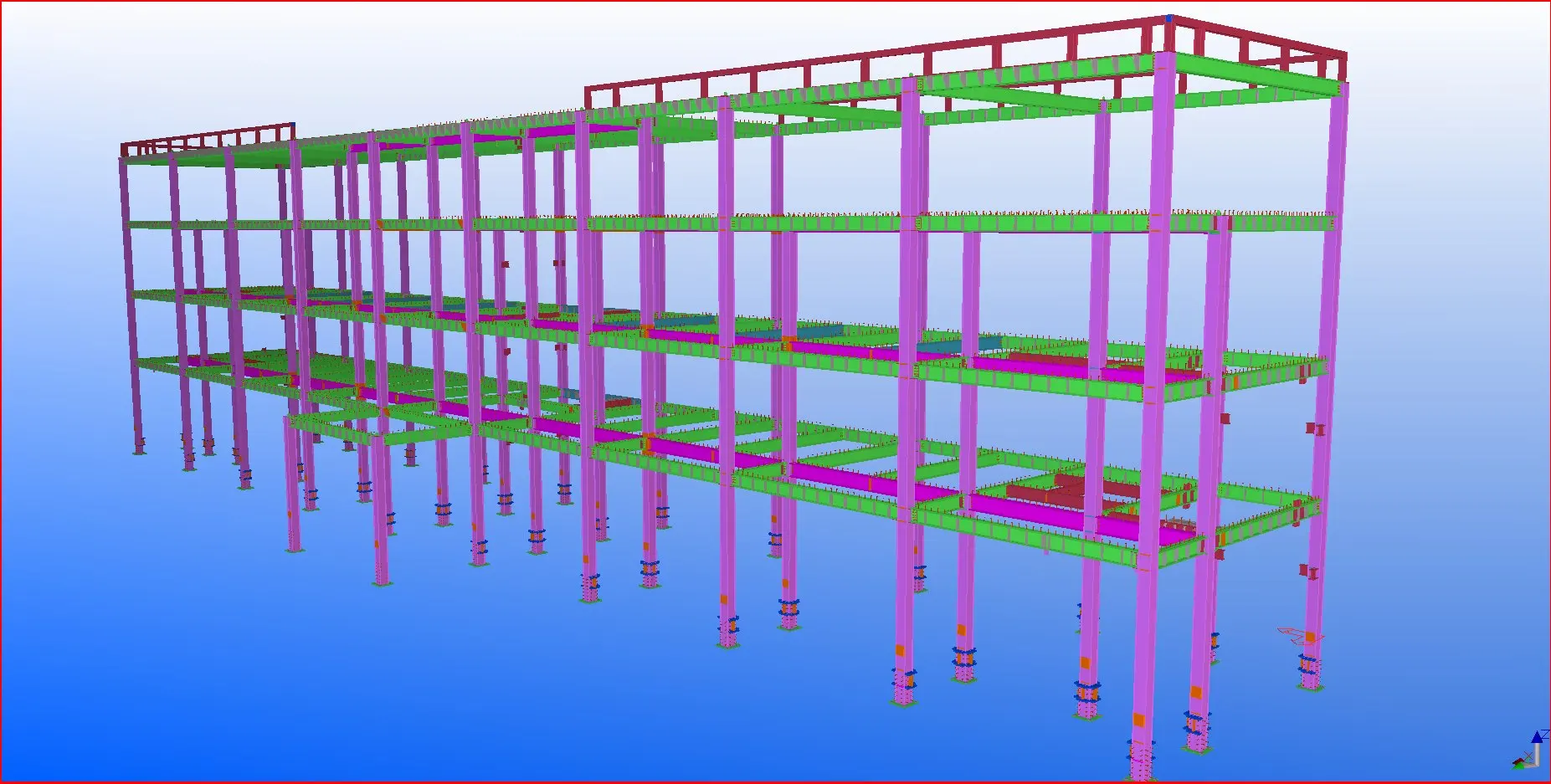

Static construction uses prefabricated steel structure to build subway stations and train support facilities. custom steel frame manufactured in-house for precision and quick assembly Its durability is strong, can withstand the load generated by the huge flow of people and train operation, provide reliable support for the transportation infrastructure, and ensure the long-term safe stable operation of subway stations and related facilities.

- Overview

- Recommended Products

Product Description

Specification

item |

value |

Tolerance |

±1% |

Standard |

GB |

Place of Origin |

China |

Anhui |

|

Delivery Time |

15-21 days |

Grade |

Q235 |

Brand Name |

AHDZ |

Model Number |

metro excavation support |

Type |

Heavy |

Application |

Frame Part |

Product name |

metro excavation support |

Color |

Customized Color |

Size |

Costomers' Requirements |

overview

Products Description

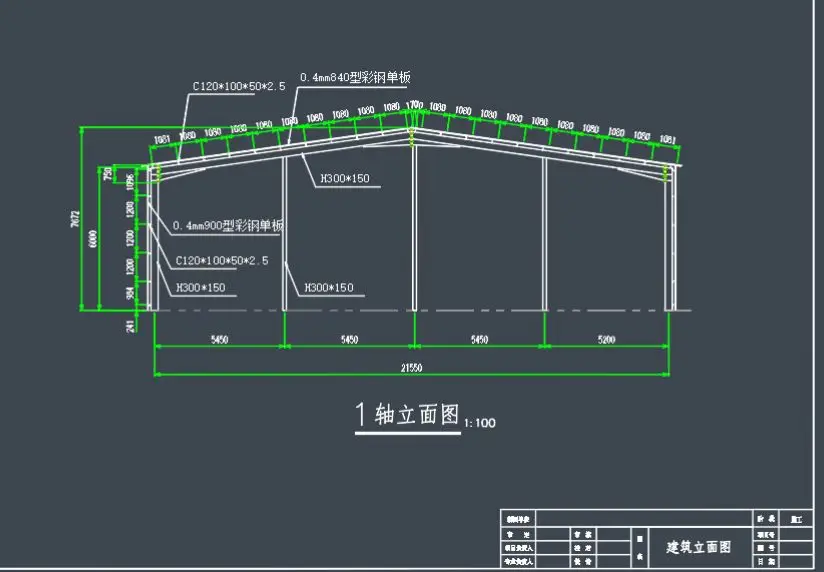

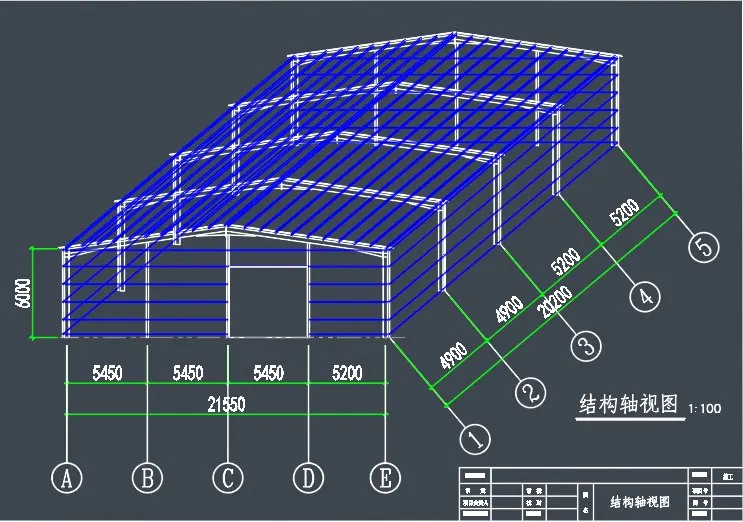

Steel structure buildings

Steel structure buildings are emerging as a favored choice in the construction industry due to their superior performance and environmental friendliness. Compared to traditional concrete structures, steel structures use steel plates or section steel to replace reinforced concrete, offering higher strength and better earthquake resistance. The components can be prefabricated in factories, allowing for rapid on-site installation and significantly reducing construction timelines. Moreover, the recyclability of steel greatly minimizes construction waste, making it a greener and more environmentally friendly option, which has led to its widespread adoption in both industrial and civil construction projects.

To better provide you with a solution, we need the following information

- Location (Where will the building be constructed?): Country and region.

- Dimensions: Length × Width × Height in meters.

- Wind Load (Maximum wind speed) in kn/m², km/h, m/s.

- Snow Load (Maximum snow height) in kn/m², mm.

- Seismic Rating.

- Whether a brick wall is needed, if so, specify 1.2 meters high or 1.5 meters high.

- Whether insulation is needed, using EPS, glass fiber wool, rock wool, or PU sandwich panels; if not, metal sheets are also an option.

- Number and dimensions of doors (width × height in mm).

- Number and dimensions of windows (width × height in mm).

- Dimensions: Length × Width × Height in meters.

- Wind Load (Maximum wind speed) in kn/m², km/h, m/s.

- Snow Load (Maximum snow height) in kn/m², mm.

- Seismic Rating.

- Whether a brick wall is needed, if so, specify 1.2 meters high or 1.5 meters high.

- Whether insulation is needed, using EPS, glass fiber wool, rock wool, or PU sandwich panels; if not, metal sheets are also an option.

- Number and dimensions of doors (width × height in mm).

- Number and dimensions of windows (width × height in mm).

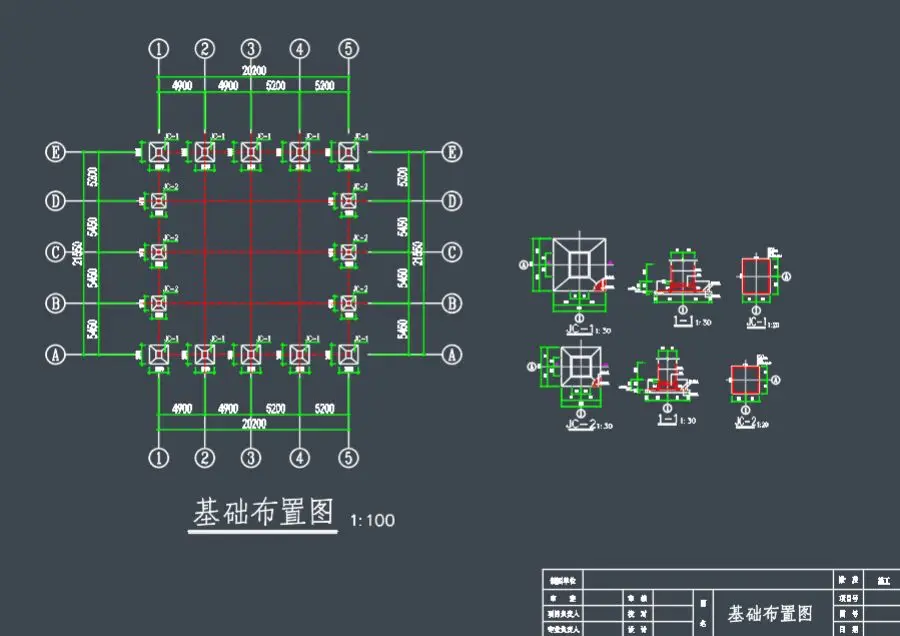

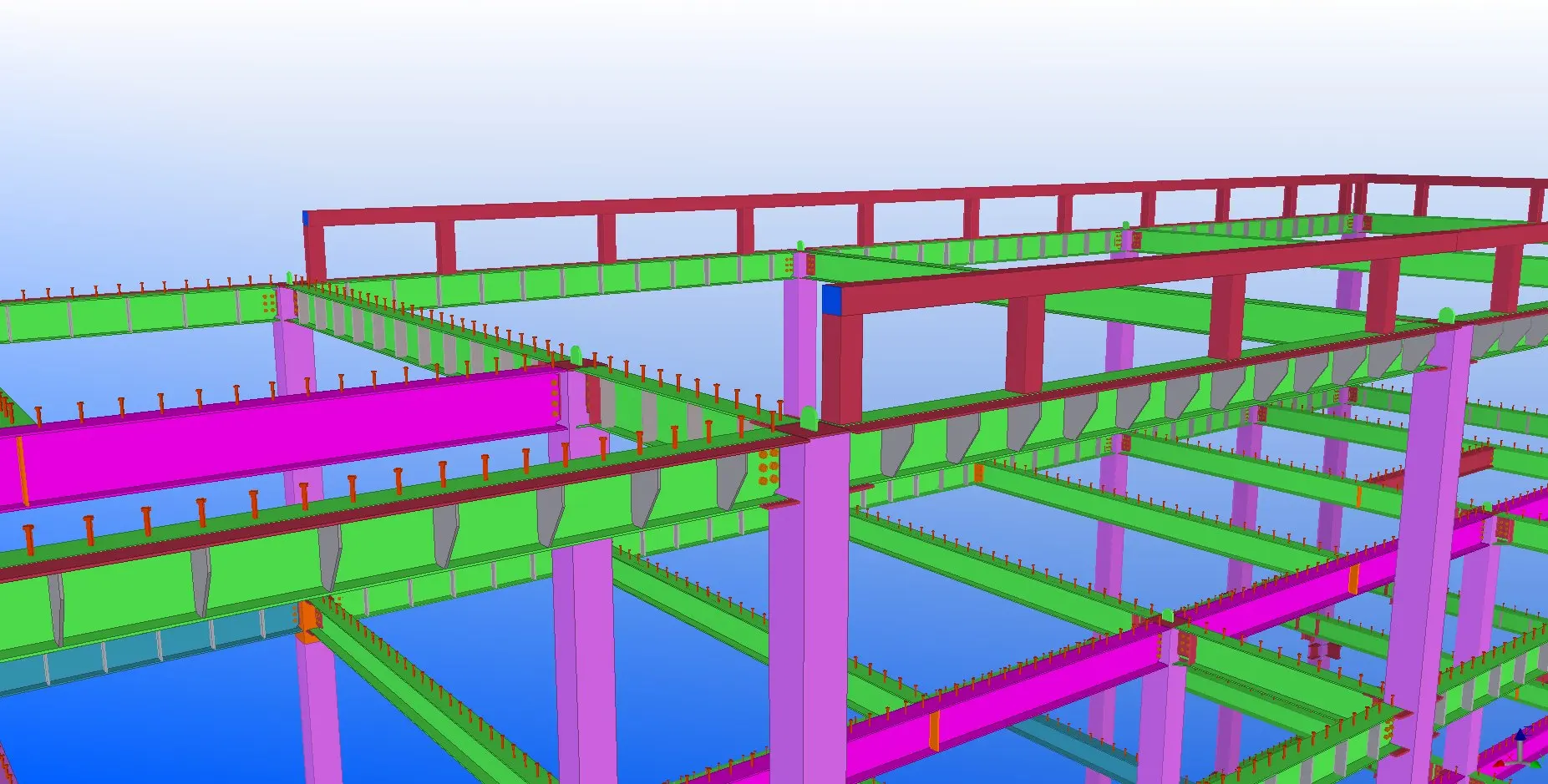

Design and Modeling

The applications of steel structure buildings are vast

Agricultural projects

greenhouses,

grain silos,etc

Industrial projects

workshops,

warehouses

factories

logistics centers,etc

Commercial projects

showrooms, office buildings, supermarkets, schools, sports venues, etc.

Why Choose Us

Anhui Dingzhu Technology Group Co., Ltd., established in 2011 and headquartered in Hefei City, Anhui Province, is a leading provider of comprehensive steel structure solutions. The company specializes in product R&D, design, sales, and services, with a focus on environmental protection, recyclability, and durability. Their product range includes light steel, high-rise steel, residential steel, spatial steel, and bridge steel structures, known for their strength, seismic performance, and cost-effectiveness.

Dingzhu Technology's commitment to modern construction standards has led to the creation of safe, comfortable, and eco-friendly environments, earning them multiple patents and a reputation for completing government projects. Their products are popular in China and exported to countries like the United States and Singapore. The company is open to OEM and ODM orders, catering to diverse customer needs and offering engineering support to meet specific procurement requirements.

↓↓↓↓↓↓We are experienced ↓↓↓↓↓↓

Details Images

Steel Structure Apartment Residential Building |

||

Item |

Specification |

|

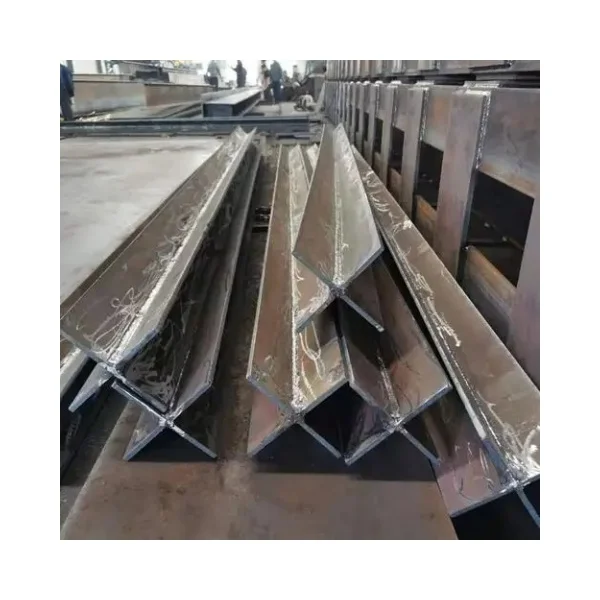

Steel beam |

I-Beams (H-Beams or W-Beams),Hollow Structural Sections (HSS),Channel Beams (C-Beams),Angle Beams (L-Shaped Beams),T-Beams,etc |

|

Steel column |

H-Beams,I-Beams, Pipe Columns, Box Columns, Steel-Concrete Composite Columns |

|

Steel purlin |

C Purlins,Z Purlins |

|

Downpipe |

PVC Downpipe, Cast Iron Downpipe, Aluminium Downpipe , GRP (Glass Reinforced Plastic),Downpipes,Copper Downpipes |

|

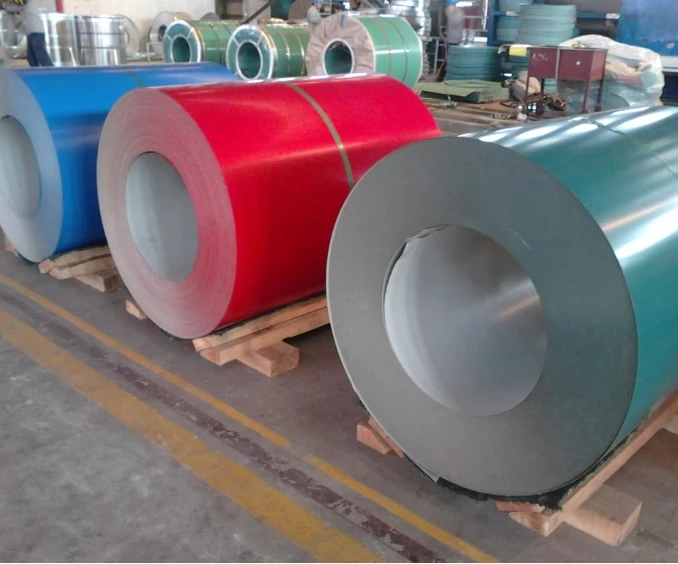

Roof material |

Metal Roofing,Clay and Concrete Tiles, Slate, Fiberglass and Asphalt Roofing,Membrane Roofing (e.g., EPDM, TPO, PVC),Green Roofs (Living Roofs),Single-Ply Membrane, Roofing Felt (Underlayment) |

|

Wall material |

concrete hollow blocks, lightweight concrete blocks, lightweight,concrete sandwich panels, gypsum boards, glass fiber reinforced cement panels (GRC), prefabricated metal frame walls, and stone walls. |

|

Door |

Aluminium door |

|

Window |

Aluminium window |

|

Gutter |

Stainless steel gutter/UPVC gutter |

|

Custom Production Processing

At our state-of-the-art manufacturing facility, we specialize in custom production processing tailored to meet the unique specifications of our clients. With a commitment to excellence, we collaborate closely with each customer to ensure that every detail of their custom product is meticulously crafted to the highest standards. Our expertise in precision ngineering, combined with our flexible production capabilities, allows us to deliver bespoke solutions that not only meet but often exceed expectations.

Product packaging

Partnering with professional transportation companies, we prioritize both cost-effectiveness and the secure handling of our products during transit. Our collaboration ensures:

1. Safety and Integrity: We use specialized packaging to protect products and adhere to strict safety protocols to maintain the condition of our shipments.

2. Efficient Tracking: Real-time tracking keeps us and our clients informed about the status of each shipment, allowing for quick resolution of any issues.

3. Cost-Effective Solutions: We negotiate competitive rates with our logistics partners while ensuring the highest standards of service.

2. Efficient Tracking: Real-time tracking keeps us and our clients informed about the status of each shipment, allowing for quick resolution of any issues.

3. Cost-Effective Solutions: We negotiate competitive rates with our logistics partners while ensuring the highest standards of service.

Certifications

FAQ

Certainly, here is the organized version of your customer question answers in English:1. **Are you a manufacturing factory or a trading company?** - We are a manufacturing factory. We welcome you to visit us at any time. Our quality control process and sales team will demonstrate our professionalism to you. Additionally, you will receive the best and most competitive pricing after visiting us.2. **Is your price competitive compared to other companies?** - Our business objectives are to offer the best price for the same quality and the best quality for the same price. We will do everything within our power to reduce your costs and ensure that you receive the best product for what you've paid.3. **Can you send engineers or a team to install my project?** - We provide detailed installation drawings . We can send engineers as installation directors or a team upon request.4. **Do you accept container loading inspection?** - You are more than welcome to send an inspector, not only for container loading but at any time during the production process.5. **Do you offer design services for us?** - Yes, we can design full solution drawings based on your requirements. We utilize software such as AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel), and more.6. **What is the delivery time?** - Delivery time depends on order quantities. Generally, the delivery time to the nearest seaport in China is 30-40 days after receiving the deposit.7. **How can I get a quotation for my projects?** - You can Contact Us via email, phone, Alibaba TM, WhatsAppand we guarantee a response within 8 hours.

Business Card